Importance of Proper Preparation

The importance of proper preparation cannot be overstated when it comes to por 15 metal prep instructions. A thorough preparation process is essential to ensure a strong bond between the metal surface and the por 15 coating. This involves removing any dirt, grime, or rust from the surface, as well as degreasing the metal to remove any factory oils or residues. According to online forums, many users have reported successful results by using a wire wheel on an angle grinder to remove rust and other imperfections. Others have recommended using a green scotchbrite pad to gently scrub the surface and remove any remaining debris. By following these preparation methods, users can ensure a smooth and even application of the por 15 coating, which is critical for achieving optimal results. Proper preparation is the foundation of a successful por 15 application, and it is crucial to get it right to avoid any potential problems or issues down the line.

Preparation Methods for Metal Surfaces

Methods include degreasing and sanding metal surfaces to ensure proper adhesion always using por 15 products and following specific guidelines for effective results online every time with great success always.

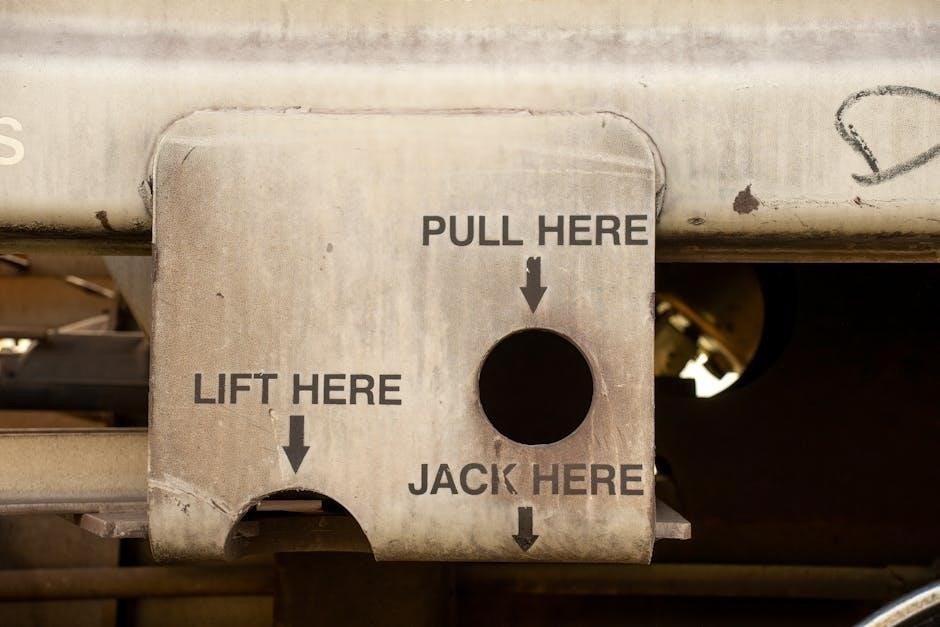

Using a Wire Wheel on an Angle Grinder for Rust Removal

Using a wire wheel on an angle grinder is an effective method for rust removal from metal surfaces. This technique is often used in preparation for applying por 15 metal prep. The wire wheel is attached to the angle grinder and used to scrub away rust and corrosion from the metal surface. It is essential to wear protective gear, including gloves and safety glasses, when using a wire wheel on an angle grinder. The process can be messy and may produce sparks, so it is crucial to work in a well-ventilated area. After using the wire wheel, the metal surface should be cleaned and degreased to ensure proper adhesion of the por 15 metal prep. This method is particularly useful for removing rust from large areas or for preparing metal surfaces that have heavy corrosion. By using a wire wheel on an angle grinder, individuals can effectively remove rust and prepare their metal surfaces for the application of por 15 metal prep. The result is a clean and rust-free surface that is ready for further treatment.

Applying Por 15 Metal Prep

Applying por 15 metal prep involves brushing or spraying the solution onto the prepared metal surface carefully following instructions for optimal results and effectiveness always matters greatly online every time.

Instructions for Application and Drying

Instructions for application and drying of por 15 metal prep are crucial for achieving the desired results. The solution should be applied using a brush, as it levels out nicely and provides a smooth finish. It is recommended to apply a thin coat, allowing it to dry completely before applying additional coats. The drying time may vary depending on the environmental conditions, such as temperature and humidity. It is essential to follow the instructions carefully and allow the solution to dry according to the recommended time frame. This will ensure a strong bond between the metal surface and the por 15 metal prep, resulting in a durable and long-lasting finish. Proper application and drying techniques are vital for achieving optimal results and preventing any potential issues or problems. By following the instructions carefully, users can ensure a successful application and achieve the desired outcome. The solution is easy to apply and dries quickly, making it a convenient option for various metal surfaces.

Benefits of Using Por 15 Metal Prep

Benefits include enhanced paint adhesion and rust prevention always using por 15 metal prep products correctly online every time for best results and outcomes always matter greatly in metal prep.

Enhanced Paint Adhesion and Rust Prevention

The use of por 15 metal prep instructions provides a strong foundation for enhanced paint adhesion and rust prevention on metal surfaces. This is achieved through the creation of a strong bond between the metal and the paint, ensuring a durable and long-lasting finish. The por 15 metal prep solution gently etches the metal surface, allowing for a secure attachment of the paint or coating. As a result, the paint adheres well to the metal, reducing the risk of peeling or flaking. Additionally, the rust prevention properties of por 15 metal prep help to protect the metal from corrosion, further extending the life of the paint job. By following the por 15 metal prep instructions, individuals can ensure a professional-grade finish on their metal surfaces, with enhanced paint adhesion and rust prevention. This makes por 15 metal prep an essential step in any metal restoration or painting project, providing a strong and durable finish that will last for years to come.

Storage and Handling of Por 15

Store por 15 in a cool, dark place, using a vacuum sealer to remove air and seal the lid, maintaining freshness and safety always with proper handling techniques online.

Best Practices for Maintaining Freshness and Safety

To maintain the freshness and safety of por 15, it is essential to follow proper storage and handling techniques, such as storing it in a cool, dark place, away from direct sunlight and heat sources. Using a vacuum sealer to remove air and seal the lid can also help to prevent spoilage and maintain the product’s effectiveness. Additionally, it is crucial to keep the product away from children and pets, and to avoid ingesting or inhaling it, as it can be hazardous to one’s health. By following these best practices, users can ensure the longevity and safety of por 15, and achieve optimal results when using it for metal preparation and rust prevention. Proper handling and storage can also help to prevent accidents and spills, and reduce the risk of exposure to the product’s hazardous ingredients. This is especially important for individuals who work with por 15 regularly, as prolonged exposure can have adverse health effects.